Waste hot water is one of the recoverable energy sources for all companies. This energy is recovered and reused in company by heat recovery systems instead of being disposed of. When energy costs and low payback periods are considered, the heat recovery system from hot waste water is a profitable investment.

The heat recovery system from waste hot water reduces the energy intensity of company It provides benefits to the national economy by reducing energy consumption and contributes to reducing carbon footprint by decreasing the amount of CO2 released into the atmosphere.

Textile dyehouses have a large amount of dyed waste hot water capacity. With the waste hot water heat recovery system, dyehouses will act in accordance with the ” Integrated Pollution Prevention and Control Regulation for the Textile Sector ” published by the Ministry of Environment, Urbanization and Climate Change.

Developed by Ozlu Engineering, the waste heat recovery system from waste hot water is a compatible solution for all industries, especially in textile dyehouses. The system is designed for waste hot water with a flow rate ranging from 10m³/h to 100m³/h and a temperature of 50 °C or higher.

The advantages of a heat recovery system from waste hot water are as follows:

– Reduction of energy cost

– Increase in production speed

– Decrease in energy intensity

– Reduction of carbon footprint

– Low temperature drainage of waste water

– Electric energy savings in pumps with inverter control

– Short-term return on investment

– Strong competition

WORKING PRINCIPLE

WORKING PRINCIPLE

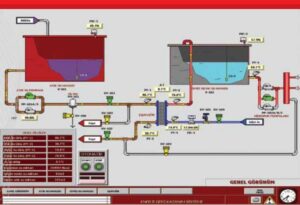

The waste hot water generated from all processes in the company is passed through a mechanical filter and then collected in the waste water tank.

The hot water sucked from the waste hot water tank by the waste water pump is pressed into the self-cleaning automatic filter. After the automatic filter, the primary circuit of the water-to-water plate heat exchanger is pressed. Cold water from the soft water tank is sent to the secondary circuit of the heat exchanger. Thus, the soft cold water is heated by the energy of the waste hot water. Thanks to the plate heat exchanger, soft hot water is produced at temperatures up to 7°C below the waste hot water temperature. While the waste hot water is drained in a cooled state, soft hot water is sent to the hot water tank.

The plate heat exchanger used in the system is cleaned with an automatic backwashing system at certain intervals.

The waste heat recovery system from hot water has a fully automatic PLC-controlled remote monitoring system. Thanks to this remote monitoring system, the heat recovery system canbe monitored, controlled and intervened 24/7.

THE EQUIPMENT USED;